Sealing solutions play a vital role in maintaining the efficiency and safety of various mechanical equipment. The choice between dynamic and static seals can significantly impact the performance and functionality of these systems. In the end, you will be educated enough to understand the difference between dynamic and static seals to determine the best option for your specific sealing needs.

Table of Contents

ToggleDynamic Seals Definition

Dynamic seals serves as a barrier between the two moving surfaces. It does not matter that the surfaces are moving in reciprocating motion,oscillating, linear or in rotary motion, dynamic seals intend to function effectively. You will find their uses in a wide variety of industrial and mechanical applications.

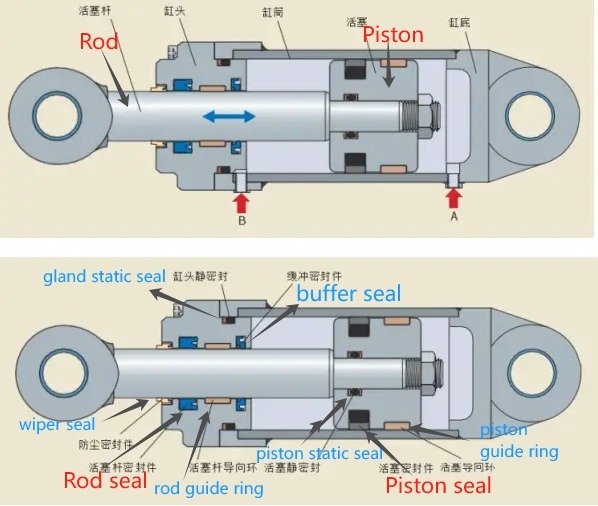

For example, inside the hydraulic cylinders, piston dynamic seals prevents the leakage of hydraulic fluids. In addition, wiper dynamic seals outside of hydraulic cylinder works to prevent contamination from entering the cylinder.

Types of Dynamic Seals

There are various types of dynamic seals, each one is unique with some specific functions. Generally, their usage depends on the temperature, pressure, material of the surface and the type of motion. There are following dynamic seals example:

- Lip Seal

- Mechanical Seal

- Gland Seal

- Rod Seal

- Wiper Seal

- Piston Seal

- U-Seal

- Bellow Seal

- Diaphragm Seal

- Pneumatic Seal

- Spring Energised Seals

Static Seals Definition

Static seals creates a barrier between two uniform surfaces to prevent seeps. Its a most compressed sealing solution mainating a reliable seal in harsh conditions. It compresses between two surfaces and creates a block to prevent any kind of leakage.

For example: In a piping system, flanges connects different pipes and equipments. They ensures the leak proofing by creating a tight compressible seal between two flanges.

Types of Static Seals

Static seals are of various types. However, you have to choose specific one considering multiple factors. The list of factors including temperature, pressure, and material of the surfaces etc. Here are the different static seals example:

- O-Rings

- Gaskets

- Diaphragm Seal

- Bellow Seal

- Flat Seal

- Clamp Seal

Dynamic Seal vs Static Seal

When selecting a seal for your application, understanding them is essential. For this, take a look at their detailed comparison below:

1. Material Composition

Dynamic Seals: These are made of high-quality and sturdy materials to bear consistent abrasion. This material composition can ensure the efficient working of dynamic seals under constant motion without losing their form. The material composition of dynamic seals includes:

- Polymers (Polyurethane and Polytetrafluoroethylene)

- Metals (Bronze and Stainless steel)

- Elastomers (Silicon, Nitrile, HNBR, and Fluorocarbon)

- Composite Materials (Graphite and Ceramics)

Static Seals: Static seals are manufactured with durable materials. This way, you will get a static seal that consistently prevents seeps between stationary equipment. The common composition of static seals includes:

- Metals (Aluminum and Copper)

- Elastomers (Neoprene, NBR, Viton, Silicone, and EPDM)

- Composite Materials (Graphite)

- Polymers (Polyethylene and PTFE)

2. Design & Shape

Dynamic Seals: The design of dynamic seals enables them to withstand the effect of various factors e.g., friction, heat, and pressure. It also ensures the tightness of the seal during the continuous motion of the surfaces. In addition, dynamic seals have a complex geometrical pattern.

Dynamic seals have a high-quality surface finish that ensures long-term working without wear and tear. The featured designs of dynamic seals include lip designs, U and V-shaped seals, etc.

Static Seals: You can ensure a tight seal with the tried and tested sealing solutions of static seals. They provide uniform compressions to ensure tight seals and resistance to wear and tear.

These seals usually have a simpler design but can vary in size and geometry. Furthermore, you can use these for sealing either end-on or radial positions.

3. Functions

Dynamic Seals: These seals can prevent leaks so that the machines can work smoothly. They prevent leakage and minimize abrasion.

Dynamic seals are also utilized for the maintenance of pressure within a machinery or system. Hence, these seals promote the efficient working of equipment in continuous motion such as sliding pistons or rotating shafts.

Static Seals: The key purpose of static seals is to maintain a blockage to avert the passage of water, fluids, or gases. These seals provide reliable sealing solutions under extreme temperatures and pressure.

Static seals maintain their sealing by their capability of working under high compression. You can use them in processes like sealing flanges and gaps, or between connection joints.

4. Maintenance

Dynamic Seals: These seals need regular maintenance because of their vulnerability to consistent movement. For maintenance, you need to regularly check the dynamic seals for any signs of degradation or damage.

In addition, suitable lubricant application to them decreases the friction effects on the seals. It is better to change the worn-out seals. You also need to install new seals properly for an extended life.

Static Seals: The life of static seals is more extended because they work in stable equipment. Hence, they do not require consistent maintenance. But it’s better to periodically check for any damage or leakage.

Important maintenance of static seals is to keep them clean. Change the worn-out seals and properly install the new seals. It can prolong the life of your equipment and the seals as well.

5. Applications

Dynamic Seals

The versatile applications of dynamic seals include:

1. Automotive Industry: These seals prevent leaks in various automotive applications. These can include the steering systems, transmission shafts, gearboxes, and engine shafts of vehicles.

2. Industrial Machinery: Various types of industrial machines such as construction machinery, agricultural machinery, petrochemical equipment, compressors, valves, turbines, and pumps utilize dynamic seals.

3. Aerospace Industry: Different aircraft components like pneumatic components, fuel lines, and hydraulic systems have dynamic sealing applications.

4. Pharmaceutical Industry: The common uses of dynamic seals are in the production process, aseptic processing, sterilization apparatus ,etc.

Static Seals

Static seals are frequently used in different industries. Following are a few applications of static seals:

1. Electrical Applications: In electrical applications, static seals are commonly used to seal electrical enclosures, connectors, terminals, and battery cases.

2. Construction Industry: The flanges, joints, valves, windows, doors, tanks, and vessels in the construction industry have static sealing.

3. Food & Beverage Industry: Different food and beverage processing equipment have food-grade static sealings. Furthermore, it is also utilized in the sealing of food and beverage packaging.

4. Industrial Machinery: These seals prevent leaking in different industrial machines, such as bearings, heat exchangers, and valve bonnets.

Final Verdict: Which One to Use

Dynamic and static seals are entirely different based on their material composition and functions. Thus, both of them are handy in specific applications. Static seals are ideal in stationary situations where the movement is non-existent. Meanwhile, dynamic seals are best when the joining surfaces are in relative motion. Thus, select the one that suits your specific needs!

FAQs

1. Can I Use Static Seals in Place of Dynamic Seals?

No, you cannot use static seals in place of dynamic seals. The dynamic seals provide sealing in moving applications. You can use the static seals in stationary applications only.

2. Can I Install the Dynamic and Static Seals in the Same Way?

The installation process of both seals is different depending on their type. So, you cannot install both seals in the same way.

3. Which Factors Affect the Performance of Dynamic Seals?

These factors include poor alignment and lubrication, harsh operating conditions, improper installation, and certain other environmental factors.

TYS is a professional dynamic sealing company that provides customized solutions for fluid power. If you want to find or improve dynamic seal products for your industry, don’t hesitate to get in touch with the TYS team.