PTFE (its trademark is Teflon) and fluoro rubber (its trademark is Viton) are commonly used raw seal materials. What is the difference between them? Is PTFE a type of rubber, plastic, or synthetic resin? What about fluoro rubber? Today, let’s learn the main differences between them so that you can use different seals correctly.

The essential difference between PTFE and FFKM is that PTFE is plastic, and FFKM is synthetic rubber.

The difference between plastic and rubber is that plastic deformation occurs when plastic is deformed, while rubber is elastic deformation. Plastic will not return to its original state after deformation, while rubber can easily recover. The elasticity of plastic is minimal, usually less than 100%, while rubber can reach 1000% or even more. PTFE’s temperature and corrosion resistance are better than those of fluoro rubber.

What is the difference between FFKM and PTFE through the following six dimensions?

Molecular Structure

The molecular structure of fluoro rubber contains elastomers, which have high elasticity and tensile properties.

The molecular structure of polytetrafluoroethylene is linear, with low tensile and bending properties.

FFKM/viton vs PTFE seals

PTFE is a thermoplastic with the following properties:

Chemical stability: PTFE is resistant to almost all chemicals, including strong acids, strong bases, and organic solvents

High-temperature resistance: PTFE can be used for a long time in the temperature range of -80℃ to 260℃ and can withstand temperatures up to 300℃ for a short time

Wear resistance: PTFE has excellent wear resistance and is suitable for manufacturing seals and bearings

Electrical insulation: PTFE is an excellent electrical insulation material.

Polytetrafluoroethylene is a polymer material with extremely high chemical resistance, heat resistance, and non-stick properties. It has excellent wear resistance and is a commonly used high-performance sealing material with many applications. It can be used to manufacture PTFE seals and accessories in various industries.

FFKM is an elastomer with the following properties:

Elasticity: FFKM has good elasticity, can withstand large deformation without permanent deformation, and has better sealing performance

Chemical resistance: Like PTFE, perfluoro rubber is resistant to most chemicals.

High-temperature resistance: Perfluororubber can be used in the temperature range of -20℃ to 200℃, and some unique formulas can withstand up to 330℃

Oil resistance: Perfluororubber has good resistance to oils and is suitable for oil seals and seals

Radiation resistance: Perfluororubber is highly resistant to radiation and is suitable for the nuclear industry and aerospace fields.

FFKM is a high-performance rubber material with excellent chemical stability, oil, heat, and corrosion resistance. It has excellent sealing performance and can be used in extreme temperatures and harsh environments. Fluororubber also has excellent weather resistance and electrical properties, making it an ideal sealing and insulating material.

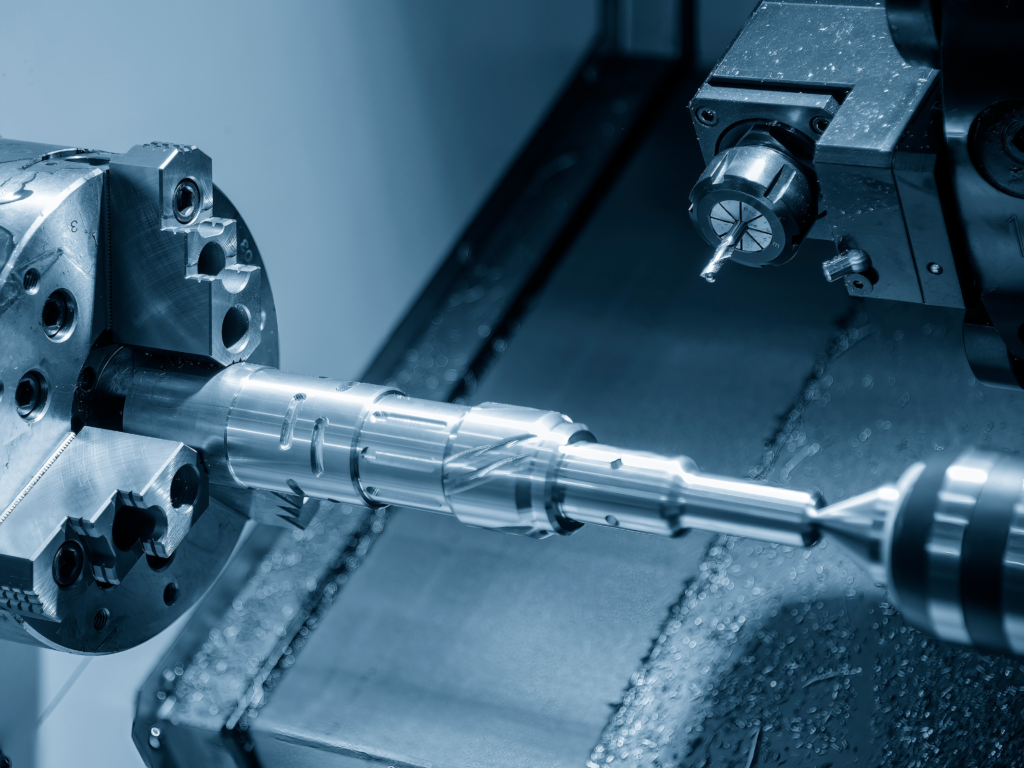

Manufacturing Process

The manufacturing process of fluoro rubber generally adopts the method of homemade rubber and calendering molding, including raw rubber preparation, mixing, calendering, molding, and other manufacturing process links

Polytetrafluoroethylene is prepared by high-temperature polymerization

Application

FFKM is mainly used to manufacture seals, pipes, and gaskets. Due to its excellent chemical stability and high heat resistance, fluoro rubber also has essential applications in mechanical parts, such as fluoro rubber O-rings, fluoro rubber gaskets, fluoro rubber seals, etc. These parts have excellent chemical corrosion resistance and are suitable for high-temperature and high-pressure environments. They are widely used in aviation, aerospace, automobiles, electronics, chemical and other fields. In addition, fluoro rubber can also be used to manufacture high-temperature tapes, oil-resistant pipes, and cable protective sleeves.

PTFE is mainly used to manufacture seals, coatings, bearings, pipes, etc., and is widely used in engineering machinery, chemicals, pharmaceuticals, food processing, oil extraction, and other fields. Its unique non-stick properties can also manufacture baking trays, grills, and ovens. It is also used in home appliances, electronics, medicine, and other fields, such as needles, delivery systems, storage containers, etc.

Material Price

FKM is more expensive than PTFE, mainly due to the high production process and cost.

PTFE is cheaper, mainly due to the lower production process and cost than fluoro rubber.

Selection Recommendations

When choosing between PTFE and perfluoro elastomer, the following factors should be considered:

Application environment: If the application environment requires high-temperature resistance, corrosion resistance, and non-stickiness, PTFE is a better choice. If elasticity and oil resistance are needed, perfluoro elastomer may be more suitable.

Temperature range: PTFE’s upper limit of long-term use temperature is higher than that of perfluoro elastomer. If the application environment temperature is high, PTFE should be given priority.

Cost: PTFE is generally cheaper than perfluoro elastomer. If cost is a consideration, PTFE may be a more economical choice.

Processing method: PTFE can be processed by extrusion, molding, machining, and other techniques, while perfluoroelastomer is more suitable for vulcanization molding. Choose the appropriate material according to the processing technology requirements.

Physical properties: If good elasticity and deformation recovery are required, perfluoro elastomer is a better choice.

Special requirements: Perfluoro elastomer may be more suitable for applications that require special requirements, such as radiation resistance and resistance to special chemicals.

PTFE and FFKM each have unique advantages, and the choice needs to be based on the actual application requirements, working environment, cost budget, and processing technology. By comprehensively considering these factors, you can ensure that the most suitable material is selected to meet the performance requirements of a specific application.