1. 简介

活塞密封 是液压缸中的关键部件,在液压缸的运行中起着重要作用。但活塞密封件到底是什么?为什么它们如此重要?活塞密封件是防止流体在活塞和气缸壁之间泄漏的专用部件。这不仅可以确保高效运行,还可以保护液压系统免受潜在损坏。

2. 了解液压缸

要理解活塞密封件的作用,了解液压缸会有所帮助。这些装置将液压能转化为机械运动,驱动活塞在气缸内来回移动。关键部件包括活塞、缸筒和连杆,它们共同作用,在机械和设备中执行各种任务。

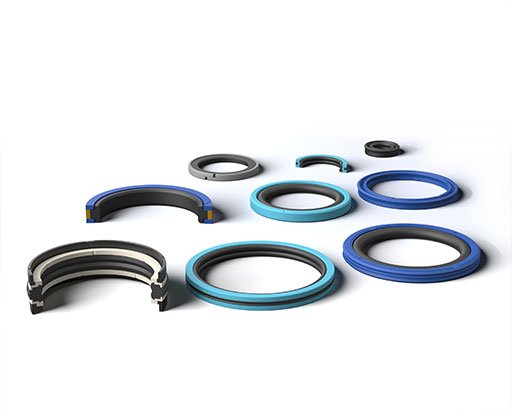

3. 活塞密封件的类型

静密封

静密封 旨在防止液压系统非运动部件发生泄漏。它们通常用于没有相对运动的固定部件之间。 这些密封件 对于保持系统完整性至关重要。

动密封

动态密封件用于零件之间有运动的区域,例如活塞和气缸壁之间。它们旨在处理因持续运动和压力变化而产生的磨损。

复合密封

复合密封件将多种材料组合在一起,以提供增强的性能。它们在强度、柔韧性和对各种条件的抵抗力之间实现了平衡,使其适合要求苛刻的应用。

4. 活塞密封件所用材料

橡胶密封件

橡胶因其柔韧性和成本效益而成为活塞密封件的常用材料。然而,当暴露于极端温度和化学物质时,橡胶会随着时间的推移而降解。

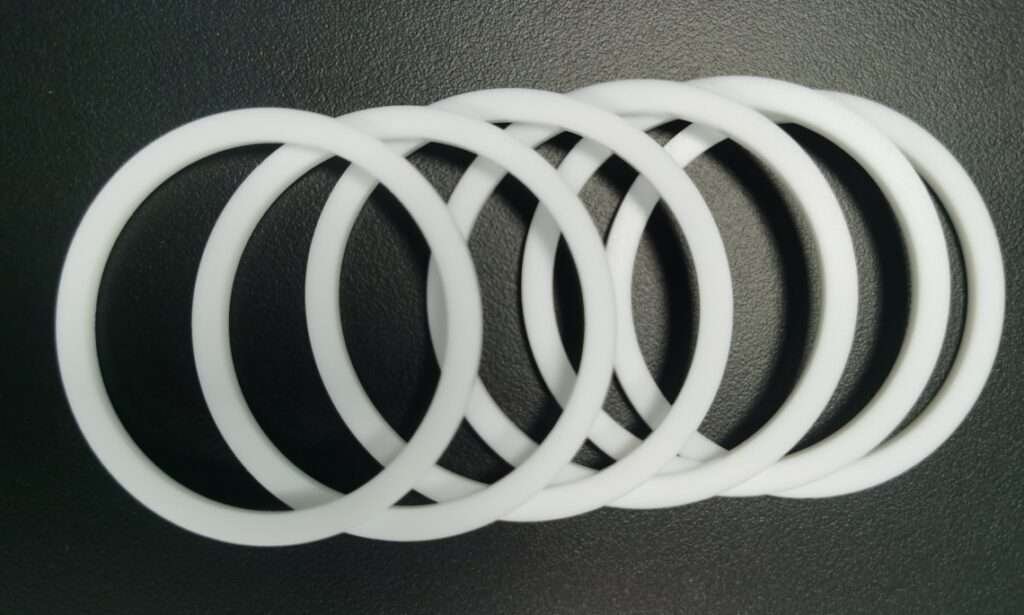

聚四氟乙烯密封件

聚四氟乙烯 (PTFE) 密封件以其耐化学性和耐高温性而闻名。它们是恶劣环境的理想选择,但价格可能比橡胶密封件更昂贵。

聚氨酯密封件

聚氨酯密封件在耐用性和柔韧性之间实现了良好的平衡。它们耐磨损,可承受中高压,是许多液压系统的热门选择。

如果您正在寻找液压缸活塞密封件,可以进入 我们的活塞密封件产品页面 ,您也可以联系 TYS团队获取免费样品供您测试,TYS是您优先选择的制造商和供应商,我们提供广泛材料和设计的活塞密封件以满足您特定应用需求,我们有自己独特的加工工艺,更短的生产流程,快速交货。

TYS携手华侨大学,共创科技创新与社会责任

作为一家专业生产活塞密封件与液压密封件的领先企业,TYS始终保持科技创新和肩负社会责任的使命。我们很荣幸成为华侨大学的实验基地,长期保持深度合作,为莘莘学子提供前沿创新技术的实践平台。通过与高校的紧密合作,我们不仅为学生创造了宝贵的实践机会,更为推动科研成果转化为生产力贡献力量。

TYS深知企业不仅仅是经济体的组成部分,更是社会发展的重要推动力。作为社会的一员,我们积极参与人才培养、创新研发,推动行业科技进步。我们相信,知识与产业的深度融合,能够为社会创造更多的福祉,并持续推动制造业高质量发展。

TYS——承载科技创新使命,推动社会进步的力量。

5. 选择活塞密封件时要考虑的因素

工作压力

密封件必须能够承受液压系统的最大压力。选择具有适当压力等级的密封件对于实现最佳性能至关重要。

温度范围

液压系统通常在极端温度下运行。选择能够承受这些温度的密封材料可确保使用寿命和可靠性。

化学兼容性

不同的液压油对密封材料有腐蚀作用。确保密封与系统中使用的流体具有化学兼容性可防止过早失效。

密封尺寸和设计

密封件必须与液压缸的尺寸和设计相匹配。尺寸不正确会导致泄漏和效率降低。

6. 活塞密封的常见问题

泄漏

泄漏是密封件安装不当或损坏引起的常见问题。快速解决原因可以防止进一步的问题。要了解有关泄漏的更多信息,您可以查看 液压缸常见漏油原因和解决方案的文章。.

磨损

随着时间的推移,密封件会因摩擦和压力而磨损。定期维护可以帮助缓解这些问题。

污染

灰尘和碎屑会污染液压系统,导致密封件损坏。实施适当的过滤和维护程序可以降低这种风险。

7. 活塞密封件的维护和保养

定期检查

定期检查密封件有助于在问题发展成为重大问题之前发现问题。检查是否有磨损、泄漏或损坏的迹象。

清洁程序

保持密封件和周围区域清洁可防止污染。使用适当的清洁剂和技术来保持密封件的完整性。

了解更多有关 液压密封件维护技巧的信息。

更换指南

根据制造商的建议或当出现明显磨损迹象时更换密封件。正确安装对于有效性能至关重要。

8. 活塞密封技术的创新

新材料

最近的进展引入了新材料,提高了性能、耐用性和对极端条件的抵抗力。这些创新正在突破液压密封技术的极限。

增强的设计功能

新的设计特点,例如改进的密封几何形状和与其他组件的集成,正在提高液压系统的效率和可靠性。

9. 结论

活塞密封件对于液压缸的正常运转至关重要。选择正确的密封件类型和材料对于保持系统效率和避免昂贵的维修至关重要。通过了解各种类型的密封件及其应用,您可以做出明智的决定,以确保液压系统的使用寿命和性能。

10. 常见问题解答

活塞密封件的主要作用是什么?

活塞密封件的主要作用是防止液压油在活塞和气缸壁之间泄漏。

活塞密封件多久更换一次?

应根据制造商的建议或检测到磨损或泄漏迹象时更换活塞密封件。点击此处了解如何更换液压缸密封件?

我可以对液压缸使用任何类型的密封件吗?

不可以,密封必须与操作条件兼容,包括压力、温度和化学暴露。

活塞密封失效的迹象有哪些?

常见迹象包括泄漏、性能下降和其他部件磨损加剧。 详细了解液压缸密封失效分析。

详细了解液压缸密封失效分析。

考虑工作压力、温度范围和化学兼容性等因素,选择最适合您需求的材料。TYS 提供 PTFE 活塞密封件 与 聚氨酯活塞密封件。您可以联系 TYS 获取。