Piston rod seals and piston seals are very important in the normal and safe operation of hydraulic systems. They have some similar features and some differences.You will know about the difference between rod seal and piston seal in this blog today.

Different positions

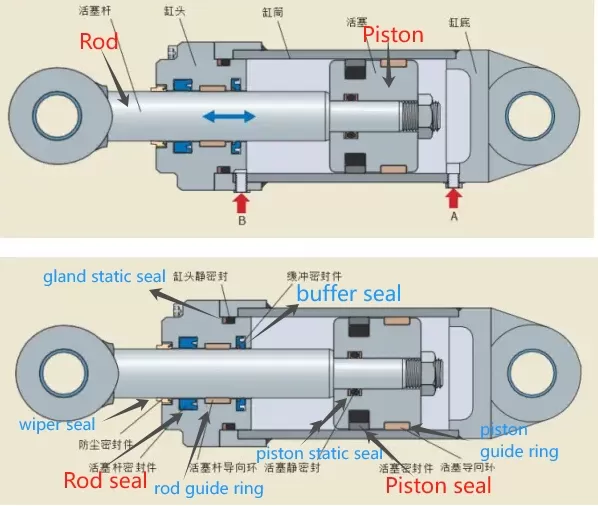

The sealing groove and piston seal are fastened to the piston.The seal mostly closes the space that exists between the cylinder wall and the piston.

In the hydraulic cylinder, the rod seal is fixed on the piston rod.It mainly seals between the rod and the cylinder gland.

Different functions

It mainly sealing element acting between the piston and cylinder wall to prevent leakage of media such as gas or liquid.It is the primary seal in the hydraulic cylinder, bidirectional pressure-bearing, and is one of the most important seals the hydraulic cylinder can withstand. If the seal is not good, it will affect the performance of the cylinder.

The piston rod seal mainly prevents external leakage of the medium and external contaminants from entering the system. It is one of the original pressure-bearing parts, unidirectional pressure-bearing, withstands considerable pressure and directly contacts the medium. Each sealing ring is tightly attached to the piston rod to achieve a sealing effect. If the seal is not good, oil leakage will affect the cylinder.

Rod seals need to be able to withstand high pressures and speeds.

Different materials

Piston seal material are usually such as PTFE, NBR, PU and POM etc., to meet the needs of different working conditions.

Piston rod seals are usually made of highly chemically compatible materials with superb sealing properties, such as PTFE, PU, FKM etc. The specific application depends on the working conditions.

Different design structures

Typically, piston seals feature one or more sealing rings with a simple design.

Rod seals or shaft seals are available in a variety of different designs ,such as lip- and U-shaped design.They typically comprise an O-ring and a sealing ring.

Advantages:

Piston seals are advantageous because they are simple in construction, easy to manufacture and maintain, and easier to use during the system’s operation.

Piston rod seals have the advantage of better sealing performance, do not allow leakage, and have a longer service life. They can tolerate high pressure and high temperature working conditions and offer a great seal to keep pollutants out.

Disadvantages:

Piston seals have the drawback of having low sealing performance, necessitating the use of additional accessories like piston membranes to increase sealing performance.

In addition, the piston seal needs to be replaced periodically, resulting in higher maintenance costs.

The disadvantage of piston rod seals is that the metal material used to prevent leakage is easily damaged and difficult to process. In addition, mechanical seals need to be injected with lubricating oil to increase the sealing effect.

The main difference between piston and rod seals is their different installation and function. Some seals can be used as both piston and rod seals. If you need good-quality piston or rod seals, visit the product page or contact the TYS team for the piston seal and rod seal catalogue.